Our sustainability statement details the environmental impact of every part and process of our textile print on demand business.

Prinfab aims to operate a sustainable textile print on demand service with minimal impact on the environment by revolutionising the way people make and buy printed textiles.

Fabric

Prinfab print on cotton, linen and polyester fabric.

All our fabrics are supplied by UK importers or manufacturers. 12% of fabrics are manufactured in the UK with the remainder overseas. 80% of fabrics are supplied by members of SEDEX and the Better Cotton Initiative.

Prinfab were the first textile print-on demand company to ensure fabrics met the requirements of EN71-3.

Ink

Prinfab use pigment and sublimation ink from Epson.

All our ink is OEKO-TEX Eco Passport certified and do not contain chemicals harmful to humans.

Our pigment inks are ECOCERT certified. This means they have been independently checked to ensure they have been made in an environmentally and socially responsible way.

Production

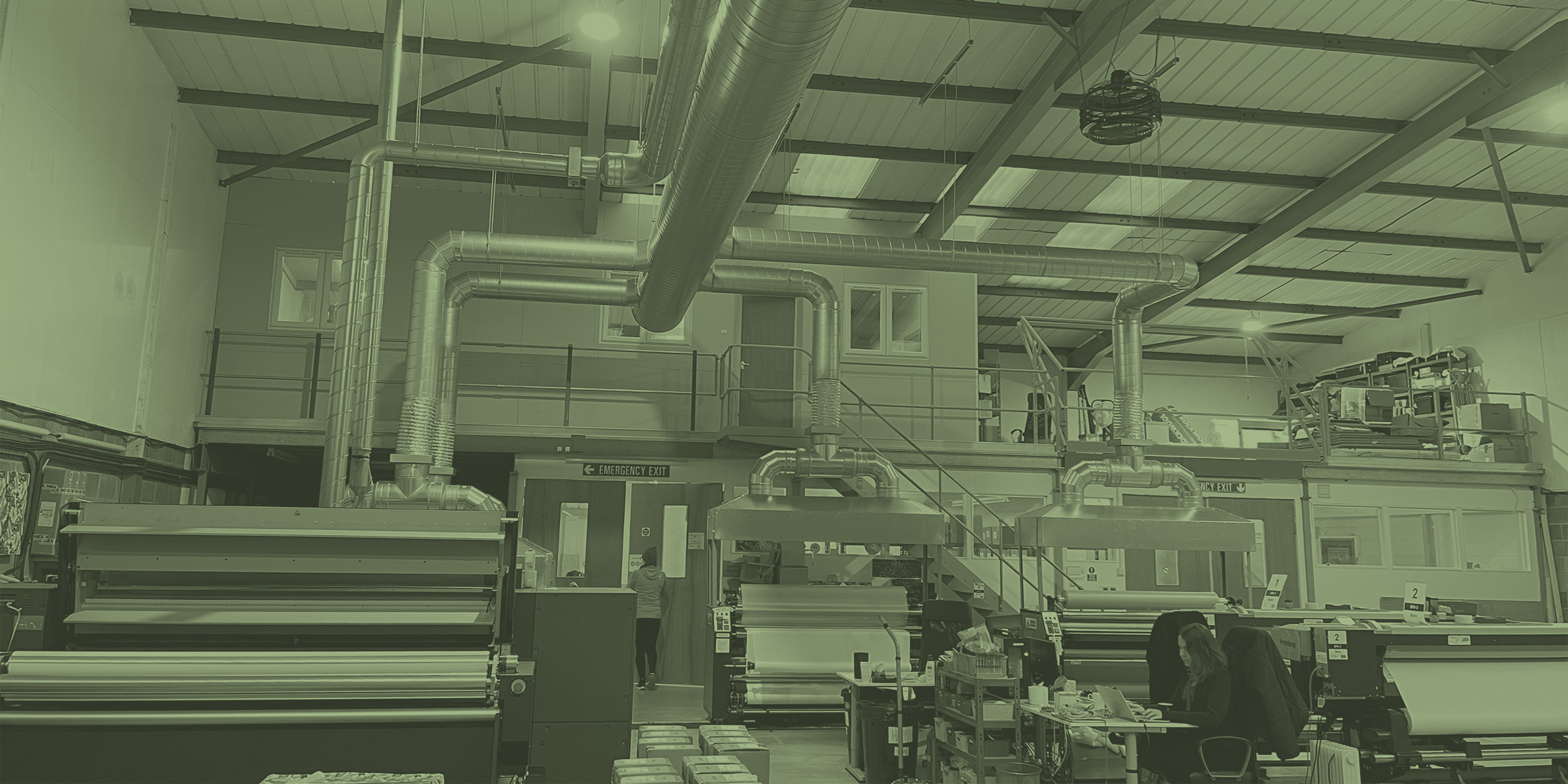

Prinfab use industrial digital direct-to-textile and dye sublimation printers from Epson.

Digital printers enable us to offer a textile print on demand service with no minimum. This encourages customers to only order what is required inherently reducing waste. 1

Both print processes are waterless. Prinfab use 0.88kWh of electricity for every m2 of fabric printed. 2

Shipping

Prinfab use environmentally friendly packaging and ship using Royal Mail and DHL.

All orders are shipped using recyclable packaging.

Royal Mail have the lowest carbon emissions of any major UK shipping company. 3

Waste

Prinfab produce recyclable and non-recyclable waste.

General waste is collected by an ISO accredited company and seperated for recycling where possible.

Bulky waste is collected by specialist licensed carriers and seperated for recycling where possible.

Milestones

- Jun 2016 Trading starts

- Aug 2017 Introduction of first organic fabric

- Sep 2017 Introduction of first UK manufactured fabric

- Feb 2019 Sublimation inks OEKO-TEX Eco Passport certified (NEP 1902)

- Aug 2019 Introduction of first recycled polyester fabric

- Apr 2021 Pigment inks OEKO-TEX Eco Passport certified (NEP 1612) and GOTS certified

- Jul 2021 All fabrics tested to ensure they meet requirements of EN71-3

- Oct 2022 Sponsor of GreenGrads, an initiative supporting graduates solving the environmental challenges faced by the textile industry

- Nov 2022 All orders shipped in recycled and recyclable packaging

- Mar 2023 Sustainability Statement published

Our Aims

Prinfab are leading the way in sustainable textile production, but recognise scope for improvement. Our team are working on initiatives to:

- Reduce energy usage to 0.6kWh per m2 of fabric printed by the end of 2025

- Recycle all recyclable waste by the end of 2025

Our sustainability statement is a working document and will be updated periodically. This document was last updated on 30 Septemeber 2025.

References

- 1"The Environmental Benefits of Waterless Digital Textile Print Ink Systems" article published by FESPA (Federation of European Screen Printing Associations). https://www.fespa.com/en/news-media/features/the-environmental-benefits-of-waterless-digital-textile-print-ink-systems

- 2Energy usage calculated by dividing total energy used in the business by total metres of fabric printed for 6 month period ending 30 Jun 2024

- 3Royal Mail sustainability statement. https://www.royalmail.com/sustainability

Loading...

Loading...